Tips and tricks for technology and design Archive - Page 2 of 3 - Mark3D UK - Markforged partner for 3D printers in the UK

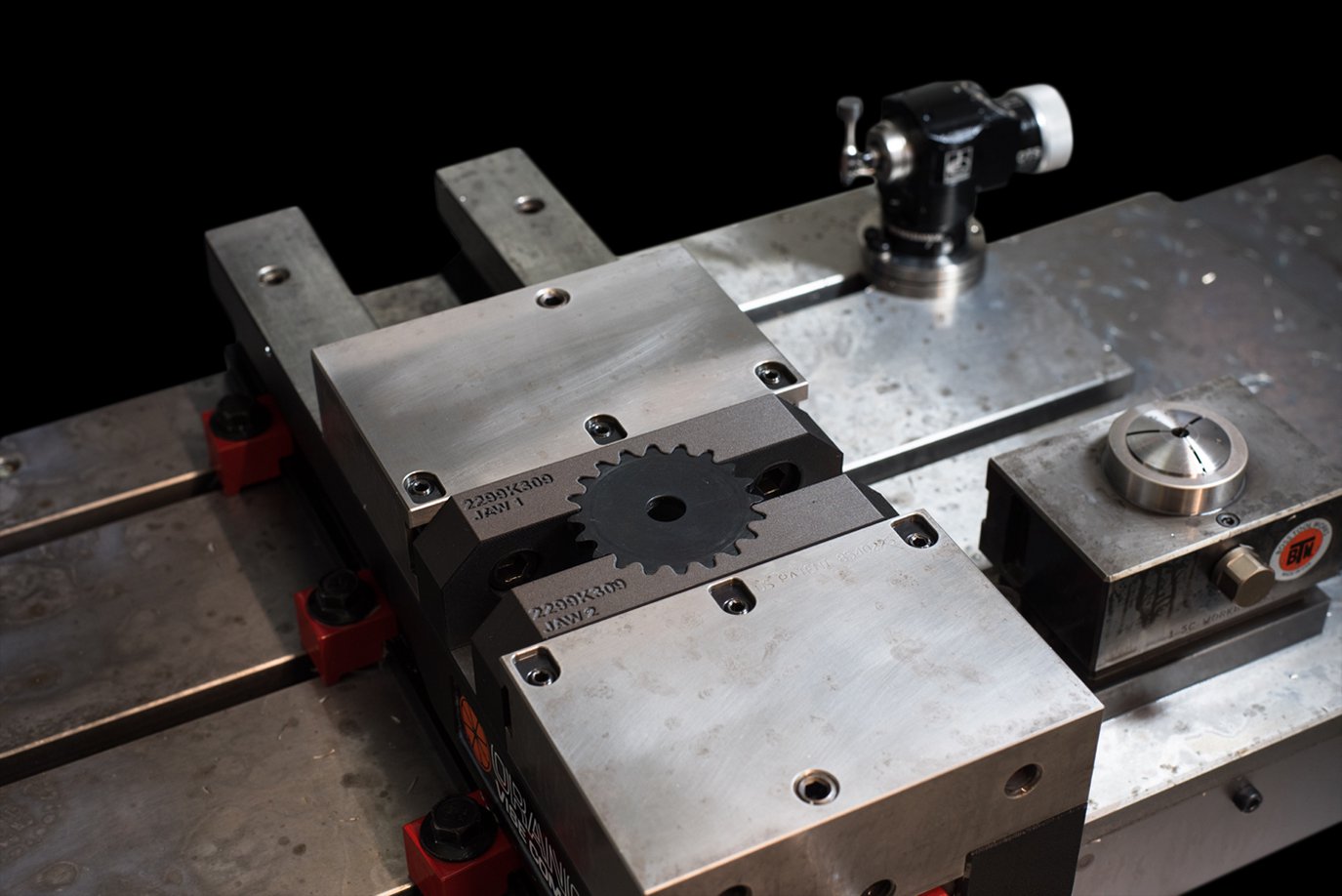

Lean Machine - Onyx Parts | Engineers at Lean Machine were having to turn down jobs because the tooling needed was often more expensive to produce than the end product. So, they...

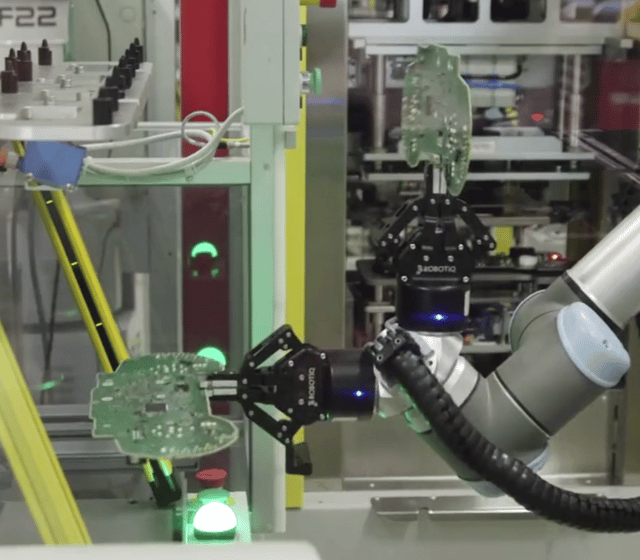

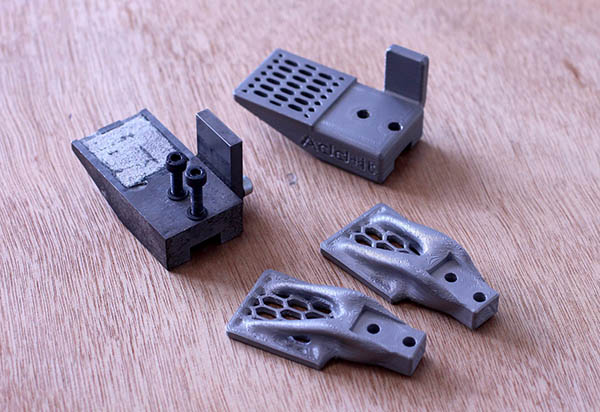

Can 3D printed robot grippers be 97% cheaper? - Mark3D UK - Markforged partner for 3D printers in the UK

Markforged Leverages 3D Printing Technology to Assist Veterans with Disabilities - Articles - Automation Alley

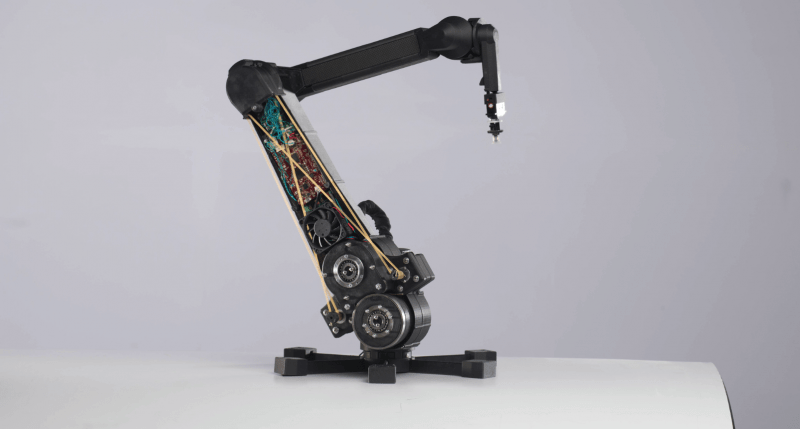

Markforged on Twitter: "Our #Onyx material is designed for heavy duty industrial applications. Move beyond prototyping straight to the factory floor. #PrintStronger https://t.co/RrTa8cFS2V" / Twitter